Location | Roma

Date | 2012-2016

Client | Società Italiana per Condotte d’Acqua s.p.a.

Design | Fuksas Associati s.r.l.

Contract furniture by Devoto Design

Even in the context of such a large and complex project, Devoto’s forty years of experience in the world of bespoke furnishings meant that the company could offer a turnkey service. In fact, Devoto not only supplied and installed more than 4000 double-curved panels, but also took care of the parametric development of the project, of the study and of the creation of a substructure capable of supporting the wooden cladding.

We are a general interior contractor able to engineer and develop complex surfaces and geometries.

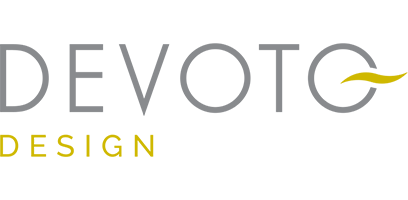

Strategically located on via Cristoforo Colombo and into the peculiar EUR district in Rome, this project involved the realization of an international convention pole and a connected hotel of 450 rooms.

The project verges on the following elements: Lama (Blade) (the longitudinal planned hotel) and Teca (Case), that is the rigid crystal shell where La Nuvola (Cloud) is inserted, representing the third element as well as the main symbol of the entire feature.

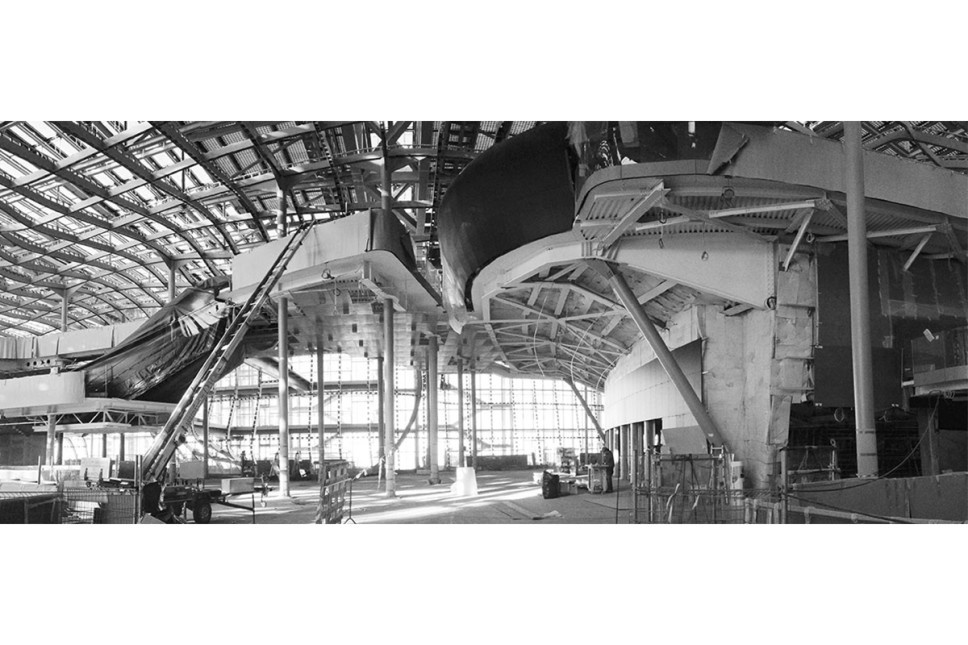

La Nuvola is an organic suspended element, protected by a semi-transparent cloth that gives it an intangible and aery nature. Inside of it we can find the Auditorium, with about 1700 seats, some cafeterias and the ancillary spaces for the different activities.

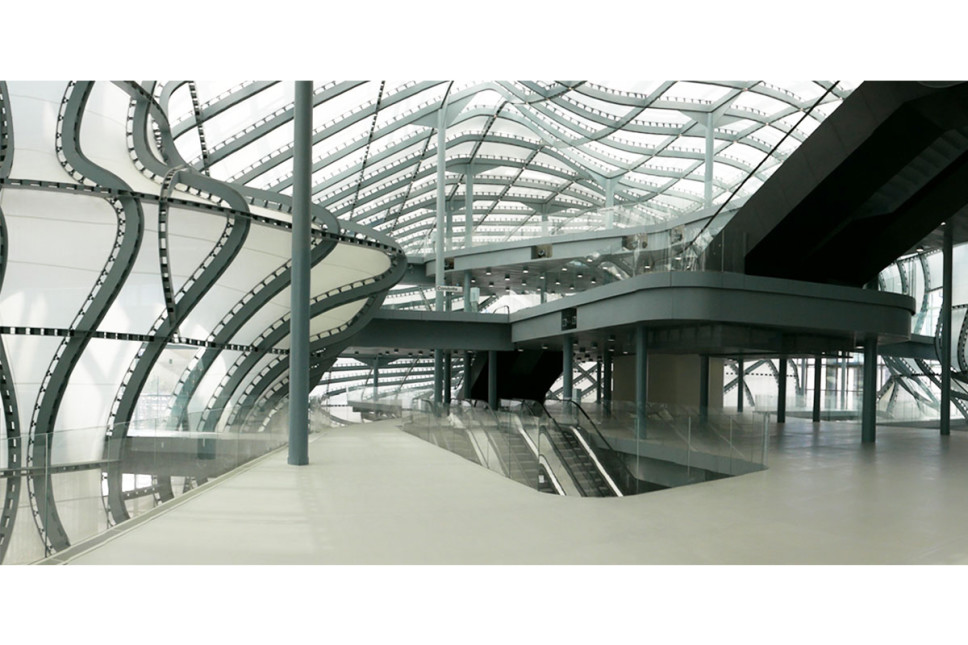

For Condotte S.p.A. Devoto realized the internal and external double-curved cladding of the Auditorium, taking also care of the metal substructure that allowed the wooden surface fix on the structural ribs of the entire building. The internal shell, a cherry wood continuous surface, stretches from the flight of steps clad with solid cherry wood floor that follows the sinuosity of the volumes, the geometry of the shape and the grain of the essence. The outside, in black timber, draws the shape of the Auditorium and the big entrance gate of the foyer, always consistent with the curves and the surface.

Devoto was assigned with the Executive Engineering too, with a dedicated team that worked with Cloud Design, a staff of specialist designers led by prof. Stefano Converso Ph.D. from the University Roma Tre. They developed a dedicated procedure, specific for the following operations: geometric optimization of the original project, development and management of the tessellation, study of the local deformation of the panels, construction drawing of each of more than 7000 panels. The great flexibility of this procedure allowed a constant discussion with the Construction Management and with the Art Direction as for the perfection of hundreds of formal and structural details. A massive operation of mass customization where the digital project, totally controlled tridimensionally, brought to several procedures (routines) specifically developed for the control of each panel and included all the connected operations, such as piercing, back-carving, pantographing, milling and numbering of all the metal and timber components. This last operation, carefully obtained from the digital model as a parameter inside the complex data management system of this particular project, marked every panel as a single piece.

All the components were extracted by transferring all the data straight from the project geometries. This requested integrated work and intense communication within all the company staff, especially between the Design Area and the Purchase & Logistics Department.

The complexity concerning the wooden elements was taken on an extreme level by integrating the steel substructure into the engineering system too. All the metal components generated by the 3D model were sent straight to the involved manufacturing companies. Therefore the project needed to take into account some production methods, some necessary tolerances and assembly procedures for each and every element – the pieces were completed by punctures and were encoded according to a specific nomenclature.

The result is a highly complex model, the outcome of software made of more than 27 dedicated programmes and their connected sub-routines, developed specifically for the work team led by architect Stefano Guarnieri, senior developer of the Cloud Design team, and specialist in construction building.

La Nuvola is undoubtedly the result of a teamwork – the mix of aesthetic/formal requisites and production needs together with economical and time parameters, was possible thanks to specific know-how and a multi-disciplinary staff.

Photo Credit: Simona Strozzi, Andrea Ricci, Marco Olivieri

@simona strozzi

@simona strozzi @alvisikirimoto

@alvisikirimoto